OK….Let’s build

If you’re reading this, you may have visited our new taproom, wine bar, pizza kitchen, coffee roasters(ish) and general community space…

Josh putting up the road signs

My name is Josh, and I am the founder of Everyday Brew Co. So, for the first few months between July and September, I hired a storage unit in Uckfield and started assembling everything a restaurant needed. Now, we did not have the budget a restaurant really needs. I budgeted 50k to do everything and… well… we’ll come onto how that really wasn’t enough.

First of all, that’s a tiny budget. Why? Well, that’s all I could rustle up. I don’t come from wealth and I didn’t want to lean on family to do this. So I invested all I had — around 7k. I borrowed another 5k from Freyja… the beautiful, long-suffering Freyja. She’s my partner in crime and the looks behind this project. The rest of the money was from a government-backed business start-up loan and a much less generous business start-up loan.

The business start-up loan was very hard to get. Luckily I’ve done business plans before, but it was long nights of planning, forecasting, and jumping through hoops for that main chunk of funding. The rest came from a really awful loan — in terms of the cost to pay back, it’s eye-watering. You can’t just get a personal loan either, because that’s fraud, but I certainly considered it. I also sold my house to make up the shortfalls when the budget didn’t stretch to where we needed it to.

So yeah… before we could even build, it was a LOT of paperwork. All done in the wee hours of the night, when everyone else slept. I beavered away on the laptop to get the funds needed to start this baby off. While we waited for the building lease to sign off, I began to search high and low for everything we needed.

You have fridges. So many fridges. Freyja really didn’t understand why I bought so many, but I feel vindicated because I kinda want more already. We needed a pizza oven, coffee machine, freezers, sinks, shelves, more shelves, a coffee roaster, plates, cups, cutlery, trays… I could keep going. Oh yeah, and more fridges. Display fridges are a separate category, so you’ll need those too. And a refrigerated deli counter apparently just counts as a deli counter, so one of those as well.

I started hiring a van and taking friends to London on weekends in search of deals. The thing with buying second-hand is you need to know what you want, what’s worth it, and you need to be a real haggler. I got turned down a hundred times, but dangling the carrot of “I’m half an hour away with cash in my pocket” works wonders. Plus, you rely on people letting Facebook sellers down, and then you strike.

The sad thing — and a good reminder — is that I was buying from businesses closing down, and I heard so many harrowing stories. The lesson was: it doesn’t have to be perfect, it just has to survive long enough to grow and look after itself. I really wish I wasn’t opening in the winter, but dems the brakes.

Freyja and Josh in the hire van

Some highlights from my dozen trips to London: a £24,000 pizza oven for just 4k. Only trick was no one could figure out how to move it. It was 2.4 tonnes — more than most forklifts can lift. Luckily I found some guys who move MRI scanners. £1500 to move it. Phoar. That felt like a lot… but turns out it wasn’t. They thought I wanted to move something that weighed 240kg. They were very surprised when it turned out to be 2.4 tonnes. After a long argument, they agreed to move it for the original fee (they wanted 4k in total for something that size), so suddenly I wasn’t so sad about the 1.5k.

We got a display fridge for free. I found out why after me and Freyja drove 3 hours. This thing was a behemoth. Lesson learned: don’t just eyeball a picture and go “yeah that’ll fit.” This thing didn’t fit in a Luton van. The café owner was not taking it back and, between broken English, I figured he wanted to tip it on its side to get it in. Three of us, plus the Luton tail lift, just about got it in. How someone didn’t get hurt, I don’t know. But y’know… it was free. A total win.

Some less big wins: the 1k dishwasher which I tested, then promptly blew a leak upon installation. So we don’t have a dishwasher… sorry team. Hand-washing all those dough trays until summer. There was also the creepy guy — you know the Facebook Marketplace seller who makes your skin crawl. He tried to sell me everything. I had to get angry and say NO! before he stopped. Then as we left, he pointed at a table: “What about that for free?” For free? Of course I said yes. Loaded it into the van… and then he started saying he really needed £50 for it. That thing was out of the van in a flash. I was in the driver’s seat and gone. Maybe some expletives were uttered. Just a few of the nice ones.

OK. Then the day comes. We get the keys to the building. I’m so excited. The original idea was for my dad to do some of the work and an external builder to do the rest, but then the quote to build a wall was so high that me and Dad cracked heads and realised we could do it much cheaper.

Josh documenting the demo process

Now that lazy git was on a two-week holiday, so I started on my own. I began the demolition job of getting rid of the old 360 offices. First night: I finish work (oh yeah, I still had a full-time job the whole time we built this thing — I still work there three days a week so I don’t have to pay myself until the summer, which is sad but gives the baby business time to stand on its own two feet and lets me hire as many of the old 360 team as I could).

So back to the first night. I get there late. I have my hammer, my drill, and a lust for destruction. Turns out I needed more tools. Everything I tried to undo or break was having none of it. But AH HA! The shower cubicle — I can dismantle that. So I climb in, get the first half of the glass door off. Huzzah! I am a demolition god. On to the next glass door. This one was trickier, so I thought: If I bend it, maybe it’ll just come off the rails.

Turns out glass doesn’t bend. This was safety glass, and I must reveal I was quite shocked when, in the dark of the upstairs office (no torch, no power), the glass exploded. My face, eyes, arms — everything was covered in glass dust. I hobbled downstairs and tried to wash the glass off — not advised, because my hands had glass shards and… well, look, I won’t go any further.

Josh after the incident

Dad got back from holiday, came in, and prepared the office for me. He gave me a reciprocating saw. “I’ve idiot-proofed it as much as I can. It’s now ready for you to do the baby job of cutting away all the plasterboard.” …Thanks Dad. I’m literally the only man in the family without a trade, but I’m also the funniest, so swings and roundabouts.

A few weeks of cutting out plasterboard and taking out the timber… the office had 2.3 tonnes of plasterboard in it and a skip full of wood. I spent nights harvesting screws out of all the timber in a vain attempt to make Dad use the wood. In my eyes it was recycling; it matched the values Everyday Brew Co would hold. Turns out it was the wrong wood for the walls Dad was building. So 9 hours of removing nails and screws for nothing… but who’s counting? Not me!

While I was doing this, Dad built the walls. The idea: more insulation and a much better aesthetic. We’re in a warehouse, but it needed to be more welcoming — this place had to work in the winter.

Then I called in my top mates — some more manly men than me — and with the use of a scissor lift and forklift, we took down the metal construction that was the office and rebuilt half of it behind the bar to build my new office (which currently doesn’t have a staircase, but y’know… Rome and all that).

Taking down the metal construction

Ah yes, the scissor lift. Let’s rewind. Day 6 of the lease, the night before I go on holiday to Sardinia, I’m having the coffee roaster delivered by a friend and colleague who did the 11-hour trip in a 7.5-tonne truck — because Gary’s a legend.

As I’m winding the roller shutter down: BANG! Sparks everywhere. Yeah, that was the roller shutter breaking. A four-week delay to get it fixed, putting the whole project behind, wasting £400 of scissor-lift hire and costing £4000 to repair. This was the big “project catastrophe moment,” the stone in the running-bike wheel that gets you right between the legs.

We found the money. Unfortunately, as I speak to you now — three weeks in — the log burner and coffee roaster don’t have flues, because that’s where the money came from. They’ll come, just more sold-house money. Money that was meant to buy Freyja a house back is now going into sorting that, and all the credit card debt. All of it. This project has absolutely battered the credit rating into the ground.

Ok, back to the build. We moved the office and built the walls. Dad’s now onto building the bar, and I’m onto what turned out to be my most hated job — and to think I was excited about it. If you check the original pictures that shows day one of the build, you’ll see the disgusting floor.

Me and Freyja, when we first dated and worked for 360°, actually cleaned and painted the blue floor to make it look great. And it did. But with warehouse floors, you need to return them to concrete for a new paint to bond, otherwise within a year you end up with what we had: flaky, blue and grey, grotty, chipped, and generally not hygiene-safe.

The floor, the walls, and the stone-tiled bar were part of my vision. Yes — my wanky vision, but mine nonetheless, and I wasn’t going to compromise.

Freshly grinded floor ready to paint

After a two-day ordeal with Brandon Tool Hire, who I would not recommend, I found a local dealer in Eastbourne called Wellers, who I would recommend. I rented the floor grinder.

Oh, floor grinding. Fifty-five hours of grinding. Enough to drive me insane. I didn’t remember my headphones until night 4 of 8. The last night nearly broke me — 6pm to 4am of grinding. It took the beautiful Freyja to pep me up at midnight not to give up.

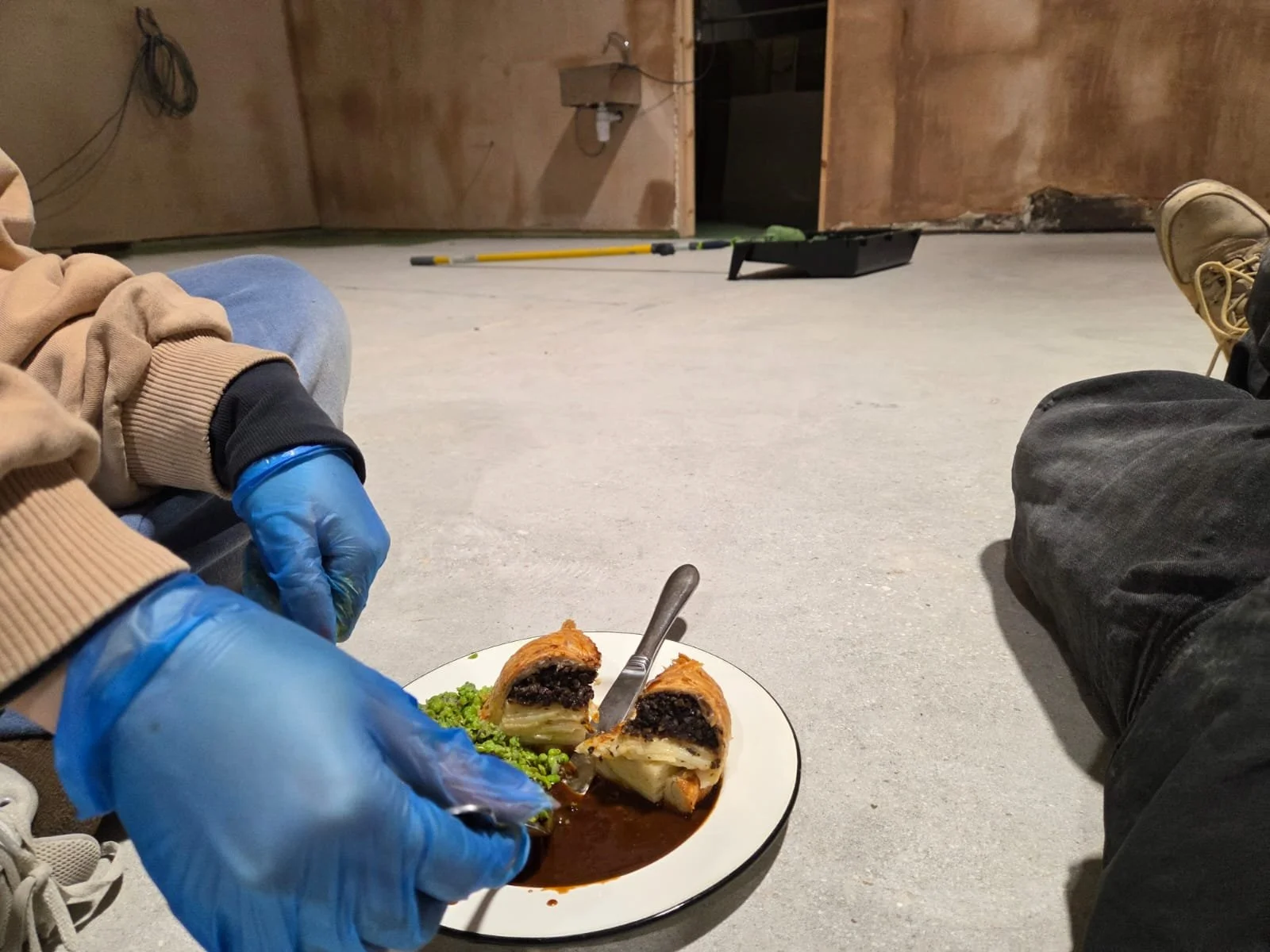

So when you come in, you’ll get a big ole smile from me if you mention the floor. Me and Freyja painted that sucker in 5 hours, which will always be a treasured memory — especially with Gerry and Alex from Vittle and Swig, an amazing events catering duo, neighbours and now besties, who brought us plates of food while we worked. The floor was done. The bar could be built.

A word to the wise: it will always be a treasured memory to have built this place with my beautiful other half, Freyja — but more so my Dad, who did all the skilled work. He worked the days, I came in as he left and worked the nights. We did it in 7 weeks.

The bar build

But employing your parent is always a minefield. His grandchildren call him Grumpy for a reason. He did amazingly — it wouldn’t be here without him. He even worked a Sunday, which he has never done in all the time I’ve known him. He’s a very holy man and Sunday is his time to commune with the All Father on the sofa with a beer.

We’re a bit alike and our fuses get shorter and shorter… and it nearly came to a head. Mum got worried and pulled the emergency cord.

I turned up on Tuesday, two days before opening, after having an almighty argument over the phone about the waste pipe. Do not be fooled — not all waste pipe is equal. And even if it says the pipe is 40mm, that doesn’t mean it is 40mm.

I turned up tired, exhausted, a broken man. Doing the build with a full-time job at night, without a day off in months, next to no sleep, stressed to the core. Oh yeah — me and Freyja moved house during the build and I recorded an EP, and I helped with wine harvest (which was 9 x 20-hour shifts in a row… during the build). So yeah. I was tired. I was ready to tell Dad to royally fuck off and I think he was ready to walk.

Stu at work

I arrived with the correct pipe (turns out I didn’t order the wrong one twice — wrong the first time, second time the company misdelivered, but who’s counting anyway). I got out of my 2.9m long Vauxhall Adam with 20 pieces of 3m pipe hanging out the window, terrifying passers-by all the way from Tunbridge Wells to Sheffield Park — like some mad hatchback jousting-idiot.

Only for the one person I didn’t expect to walk through the front door.

AHHHH… mother had pulled the emergency sister cord. Dad’s favourite had been dispatched to keep the peace, calm the boys down, and make sure we kissed and made up. Probably the smartest card anybody could have played.

I had worked all night and had one hour of sleep. Dad was nine days straight. We were both tired. My sister brought the peace, made sure I could carry on, and we got the sodding waste pipe fitted. We had a sink!!

Exhausted but happy Josh

Opening night scenes

So this is just a tiny excerpt of some of the trials and tribulations of the build. Lessons to take: buy second-hand, but know it’s hard work. Always prepare for the unexpected. Don’t bend glass. Have a sister who can knock heads together and also hug you when you desperately need it. Be kind to people so that when you need favours, they help in the most unforeseen, amazing ways. Accept help — you will need it. Do it with family, but bite your tongue — they’re doing you a favour. Expect the unexpected and budget for it. Never stop believing you can do it.

This was probably the second-hardest thing I’ve ever done. I can’t count on my fingers how many times I cried while driving to and from the unit, filled with fear, regret, and stress about the build. The exhaustion has been so real. But I got it over the line, with a million people supporting me, helping me, doing more than I’ve had the chance to talk about here.

If I can pull this off, then you can achieve your dream too — however big or small.

It’s just a taproom after all.

Thanks for reading,

Josh x